Dispenser Safety

Written by: Brian Pottebaum, Director of Training Services

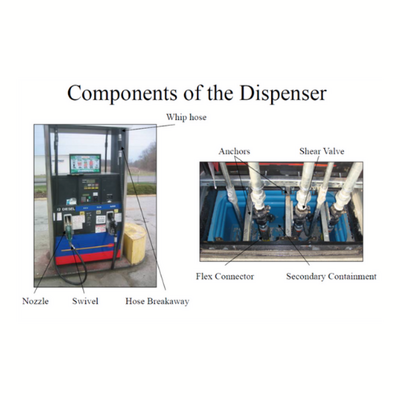

The petroleum industry continues to get more demanding. Customers want to get in and out faster. Accidents happen; that is just part of the world we live in. That is also petroleum dispensers now require certain safety components as precautionary measures to help protect your customers, and your investments.

A dispenser is the only retail device that allows a customer direct access to your UST system. Therefore, each dispenser unit should be equipped with the necessary safety components at three general areas: Nozzle, Hose, and inside the Dispenser Cabinet. The dispensing unit is regulated by the National Fire Protection Association (NFPA), specifically in NFPA 30A: Code for Motor Fuel Dispensing Facilities and Repair Garages. A basic understanding of these components is very important.

Nozzle

Each hose on the retail dispenser must be equipped with a (UL) listed, auto-closing type nozzle. A latch “hold-open device” is optional on all hose nozzles except for the Marina dispenser, which cannot be equipped with it. The auto-closing feature within the nozzle is specially designed to close automatically when the fuel tank on the customer’s vehicle is full. If the hold-open latch is in use, the auto-closing device will also disengage that latch so the fuel stops flowing through the nozzle. It is a good idea to inspect every nozzle periodically because the daily wear and tear will cause these safety features to be less reliable or even stop working.

You should also pay attention to the Useful Life “Remove-by Date” on the hanging hardware attached to the dispenser, which includes nozzles, swivels, and breakaways. The manufacturers recommend you replace the component when it has reached its full life-cycle (based on testing) to avoid potentially hazardous situations that could occur after the Remove-by Date. This predetermined date is five years plus three months from the manufacturing date. The extra three months is to allow for the time this product might typically sit on a shelf before it gets put into service.

Hose

Although retail dispenser hoses seldom exceed eight or 10 feet in length, the hose length on an automotive dispenser must not exceed 18 feet in total length. At Marinas, hose length can exceed 18 feet if adequate steps are taken to support and protect the hose from damage.

All retail dispenser hoses must be equipped with an emergency break-away (disconnect), excluding Marinas. The purpose of this safety device is to protect your dispenser from damage in the event of a drive off with the nozzle still in the vehicle. This safety device is generally located near the hose connection to the dispenser, immediately after (downstream) the short 8-12 inch “whip” hose.

If your dispensers are equipped with a hose retrieval device, make sure that the break-away device is installed between the retrieval mechanism connection (to the hose) and nozzle. If it is located on the other side of the retrieval connection, the break-away will be impaired by the retrieval device and a hazardous situation may be the result.

Dispenser Cabinet

The retail dispenser unit, or cabinet, is quite complex and there are several necessary components involved to make it function properly as it facilitates fuel transfer from the storage tank to the customer’s vehicle. Within the cabinet there is the product piping, fuel meters, solenoids, filters/strainers, and safety components like the emergency shutoff/shear valve. Pressurized fuel supply lines* require a rigidly anchored emergency shutoff/shear valve the base of at each dispenser, including remote dispensers. This device is installed in the supply line and is designed to stop the flow of product to the dispenser if the unit is struck or moved off the fueling island. The valve must also incorporate a fusible (thermal) link. This feature also allows the valve to close in the event of a fire or extreme heat. This safety device is not required on suction type dispensers.

It is also possible for some regulatory agencies to require some form of fire suppressant inside or at the dispenser, like an extinguisher, in addition to the emergency shutoff valves. These need to be maintained like any other fire extinguisher.

Emergency Electrical Disconnect

Although this safety feature is not installed on the dispenser unit, it is required at every facility that has retail dispensers. The location of the emergency electrical disconnect, i.e. “kill switch” varies at every location, however it must be located between 20-100 feet from fuel dispensing devices. This switch is extremely important when there is a need to shut down power immediately or eliminate an ignition source around spilled petroleum.

Facility safety has to be in the forefront of all fuel dispensing facilities. This is also why the UST operator training program focuses on facility safety. Preventing accidents from happening is very difficult, but being ready to respond appropriately to these situations is something every operator can handle.

*Pressurized fuel supply line is the product piping from a storage tank to the dispenser, where the product pump is located at the tank and pushing product to the dispenser, therefore under pressure.