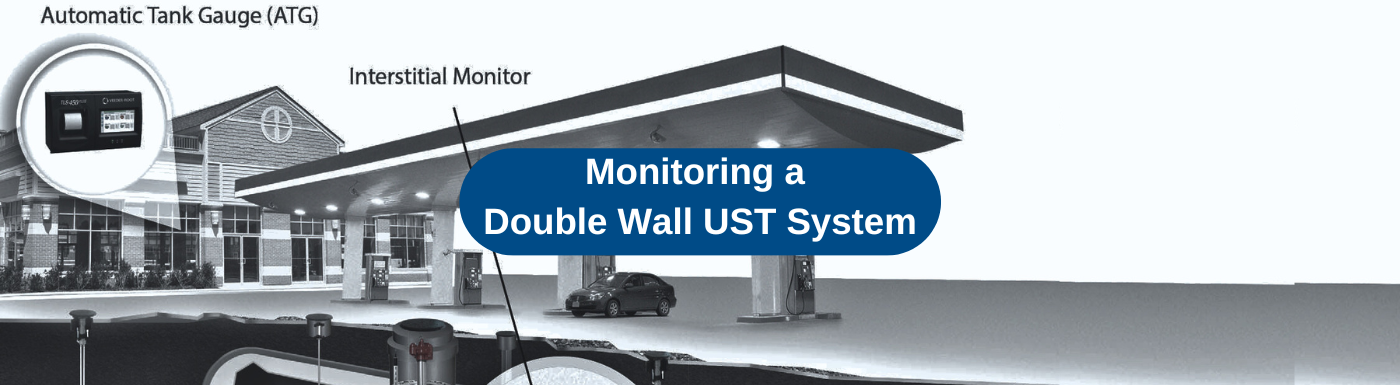

Monitoring a Double Wall UST System

Written by: Brian Pottebaum, Director of Training Services

Federal and state regulations require that underground storage tank (UST) installations and upgrades meet secondary containment guidelines. These guidelines include the installation of double wall tanks, double wall piping, and piping sumps (tank-top, intermediate, and under-dispenser containment). They also require the facility operators monitor these systems appropriately.

According to the Iowa DNR [567 IAC Subrule 135.3(9)], all new and replacement UST systems installed after November 28, 2007, must have secondary containment and be double walled. In addition, the primary method of monthly leak detection for these tanks must be monitoring of the interstice (space between the inner and outer tank walls). In most tanks, the interstitial space is monitored electronically with a liquid sensor, but some tanks do allow for a manual or “sticking” process.

The same is true for the piping system; if you are installing a new system or planning an upgrade (replacing 10 feet or more), secondary containment must be installed. This includes double wall pipe and sumps at all piping connections. Monthly monitoring of the pipe interstice and sumps is required as the primary leak detection method. The sumps can be monitored with a liquid sensor or by physically checking the condition of each sump. This method of leak detection requires that the containment be liquid-tight, meaning all entry boots, conduits, and walls are not secure. It also requires that the double wall pipe drains freely between dispenser sump and tank-top sump (i.e. piping test boots are open).

Another important aspect of secondary containment is properly documenting that you are monitoring and maintaining the double walled UST systems. This must be done to satisfy your monthly leak detection requirements. You must continually maintain 12 months worth of these monthly records. If you are monitoring electronically with liquid sensors, then you must retain the sensor status reports or manual log (if the monitor does not print a report). If you are physically checking the interstitial spaces/sumps, then you must update the manual log every time you confirm the status. Any issues indicated by this monitoring must be addressed immediately and recorded in your monitoring log.

Though secondary containment is now required on most upgrades and all new installations, it is very useful. Adequate secondary containment will capture a leak before it is released to the environment. Utilize this technology to its fullest potential and benefit from the added protection.

PMMIC provides discounts for preferred petroleum storage tank systems. Discounts can be provided for double wall piping systems, secondary containments, and electronic monitoring. Request a quote today!