Watered Down Gas

Written by: Brian Pottebaum, Director of Training Services

A vehicle pulls away from the store and dies just a few blocks from the gas pump. It won’t start and must be towed to the shop for repairs. Then it happens again to the next customer, and the next, and the next. Fuel contaminated with water was dispensed into these customers’ vehicles.

Don’t let this happen to you. Not only will you be paying for the cost to repair these vehicles, but you will also likely lose many customers as word spreads, especially if you make the local news. In addition, you must cover the expense of removing the water. Water getting into a fuel storage tank can be a very expensive oversight.

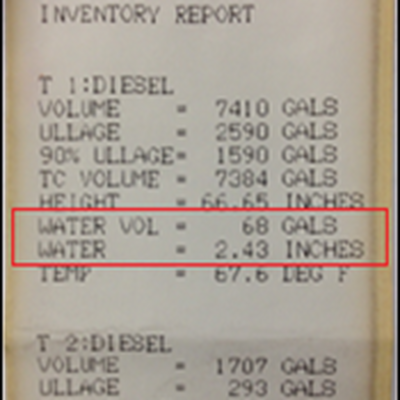

Tank operators must check the tank monitor for water in the storage tanks no less than once a month. If there is no electronic monitor, such as an automatic tank gauge (ATG), and the tanks are being manually checked with a measuring stick, make sure to use the correct water finding paste to detect any water that has entered the tank. Not all water finding pastes are created equal, so make sure to use a modified paste labeled for higher blends of ethanol and biodiesel.

Retail fuel is regulated nationally by the Office of Weights and Measures (OWM), which promotes uniformity in U.S. weights and measures laws, regulations, and standards to achieve equity between buyers and sellers in the marketplace. Therefore, they routinely check scales, meters and fuel quality at retail facilities. Typically, when dealing with retail fuel, the regulations being enforced come from NIST Handbook 44 (Specifications, Tolerances, and Other Technical Requirements for Weighing and Measuring Devices) and Handbook 130 (Uniform Laws and Regulations in the Areas of Legal Metrology and Fuel Quality).

Specifically cited in HB 130 Section 4, fuel tanks storing gasoline, diesel or other similar fuels shall not exceed 1 inch of water accumulation. Likewise, tanks storing gasoline-alcohol blends, biodiesel blends, or ethanol flex fuel shall not exceed a ¼ inch of water accumulation. In other words, if you are detecting ANY water in these blended fuel tanks, the water needs to be removed immediately.

Water intrusion can happen to any tank and can be caused by many different problems, such as loose fill caps or ATG probe caps, spill bucket drains, tanker deliveries, or even condensation inside the tank. Water will degrade the fuel quality as well as promote microbial growth, component corrosion, and ultimately system failure.

If water has accumulated and needs to be removed from the storage tank, you will need to contact a service company that can remove and dispose of the water properly.